3D LiDAR Underwater Laser Systems and Subsea Survey Support Services

Subsea LiDAR: Control the Beam, Control the Data, Control the Return

3D at Depth, Inc. is the world's leading expert in subsea LiDAR laser technology. Our advanced subsea LiDAR laser (SL) systems and subsea survey support services help customers transform the value of underwater 3D data. From data collection and processing, through visualization and analysis, 3D at Depth delivers precise, accurate, repeatable, millimetric 3D point clouds to measure, map and evaluate underwater assets and environments.

Increase Survey Efficiencies

Measure in 3D, Manage in 4D

Total Asset and Environmental Awareness

Reduce Operational Costs

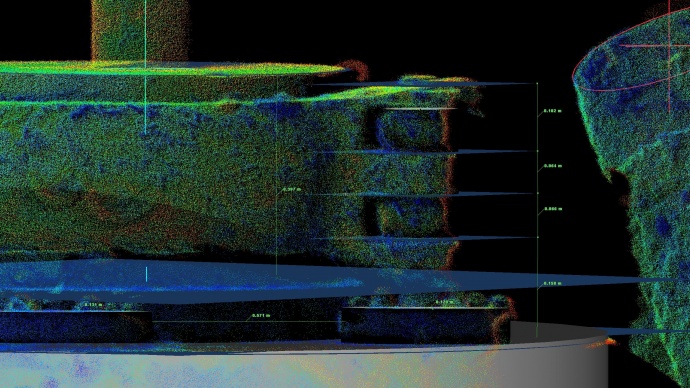

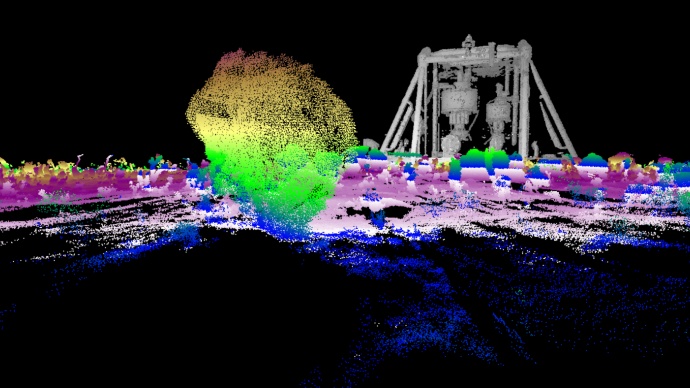

3D Underwater High Accuracy Survey Data

Modeling and Measurement of Structures and Seabed Topography

Offshore 3D LiDAR Data Collection, Management, Visualization and Analysis

Next Generation Digital Oilfield

Metrology

Measure in 3D, Manage in 4D

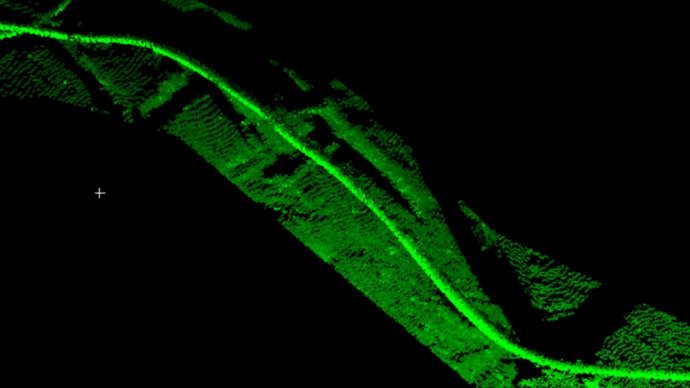

Cable Survey

Offshore Wind Renewable Energy

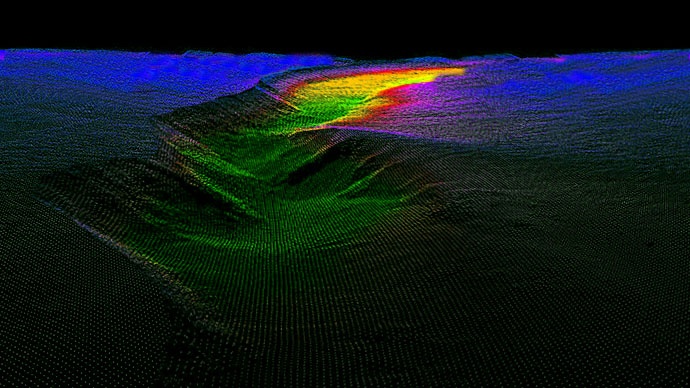

Scour Assessments

Environmental Surveys

Survey of Kingston Reef, Australia

(A collaborative project between CSIRO and 3D at Depth Pty Ltd under the Geomorphology Work Package of the AIM FSP)

Marine Habitat Surveys

Underwater 3D Scans of Naples

BBC's "Italy’s Invisible Cities,” hosted by Alexander Armstrong and Dr. Michael Scott.

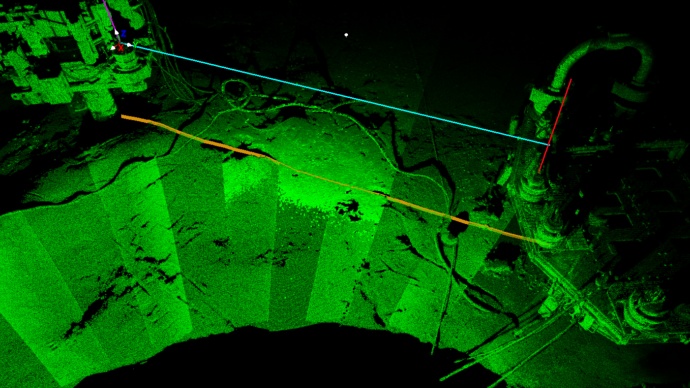

Nautical Archaeology Wrecks and Structure Scans

Introducing the "TBD Devastator" resting inside the Jaluit Atoll

Dynamic LiDAR

Subsea Metrology and Field Mapping

One Tool, Multiple Applications

One Cohesive Data Set

Long Range - Up to 45 meters

Vibration - Up to 20kHz

Leak Detection

Asset Integrity

Touchless, Non Contact

3D Measurements and Scans

SL4 LiDAR

New Titanium Subsea Rated Housing

6X Faster Scanning speeds

New Compact Onboard Electronics

Depth Range 3,000m or 4000m

Pan and Tilt Movement

Range Accuracy (+/-) <1mm

Subsea Real-Time Processing