Energy - Nuclear

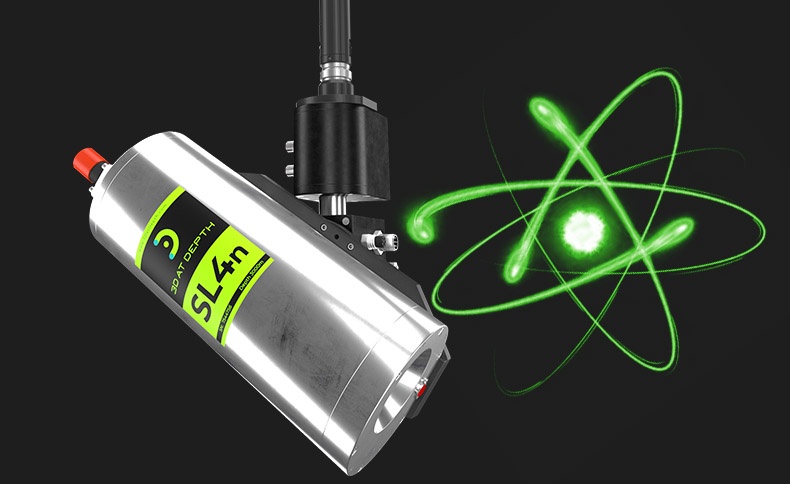

The patented SL3n LIDAR laser solution is a proven, accurate, and reliable technology that expedites crucial decisions across the nuclear supply value chain.

Innovation is ushering in a new age for the nuclear power industry. Enabling technologies deliver solutions that can increase plant economics, support operational and maintenance efficiencies, and reduce risks in the areas of health, safety, and environmental (HSE) requirements. Consistent, proactive inspections of critical assets are the best assurance for safe, cost-effective operations. The SL3n solution enables rapid, accurate, measurable, underwater, nondestructive survey campaigns. Nuclear utility operators can improve the safety, reliability, and long-term productivity of their nuclear power plants.

SL3n Benefits and Value

Optimized Survey Campaigns: Lower Risk, Reduce Production Downtime

SL3n combines patented LiDAR optical laser technology with a powerful backend software engine to generate robust, millimetric, repeatable 3D data sets that provide critical information for reliable inspections, preventive maintenance, control, and engineering analysis.

The SL3n LiDAR Difference

One Tool. One Set Up. Multiple Applications

The SL3n survey solution leverages the unique capabilities that only underwater LiDAR laser technology can deliver. One easy set up saves time and exposure, while the flexible configuration allows for multiple survey tasks to be completed in one noncontact survey campaign.

Applications and Services

SL3n Benefits and Value

Optimized Survey Campaigns: Lower Risk, Reduce Production Downtime

SL3n combines patented LiDAR optical laser technology with a powerful backend software engine to generate robust, millimetric, repeatable 3D data sets that provide critical information for reliable inspections, preventive maintenance, control, and engineering analysis.

The SL3n LiDAR Difference

One Tool. One Set Up. Multiple Applications

The SL3n survey solution leverages the unique capabilities that only underwater LiDAR laser technology can deliver. One easy set up saves time and exposure, while the flexible configuration allows for multiple survey tasks to be completed in one noncontact survey campaign.

- Visual, Underwater, Nondestructive Inspections

- Rapid Deployment and Near Real-Time Survey Data Access

- LiDAR Enabled Long-Range, Large Area Scan Coverages

- Actionable, Intelligent, Exportable 3D Data Sets

- Accurate, Millimetric, Measurable 3D Digital Twin

- Light Independent – Reduce Non-Glare/Shadow Anomalies

- Safe, Effective Surveys - Reduce Time and Lower Dose for Personnel

Applications and Services

- Foreign Object Search & Identification

- Fuel Assembly Gap Measurements

- Visual, Underwater, Nondestructive Inspections

- Metrologies - Vibration Analysis and Monitoring

- Engineering Measurements and Fabrication Support

- Training and Simulations Models – AR/VR and 3D Data Analysis

- Support for License Renewal/Subsequent License Renewal Inspections

Foreign Object Search and Identification

Detect, Locate, Identify, and Measure

Human error, structural and material degradations, and a host of other circumstances can pose safety and operational hazards to the integrity of any nuclear power facility system. Occasionally, the introduction of foreign material occurs. The admittance of these foreign materials into primary or secondary nuclear plant systems, equipment, and components cause deterioration or failures that can result in a potential shutdown. The SL3n solution enables rapid, visual, underwater, nondestructive inspections to reduce maintenance and operational shutdowns. Measurable, repeatable, millimetric 3D data sets are generated through the patented SL3n laser technology and can be exported into any standard format. Plant operational evaluations and in-depth engineering support analysis can be reviewed, measured, and accessed in near real-time for retrieval or engineering analysis.

SL3n Value and Benefits

SL3n Value and Benefits

- Rapid, Underwater, Nondestructive Survey Campaigns

- Entire vessel inspection (when core plate removed) completed in 40 minutes from a height of 37 feet (11.27 meters).

- Borate crystals identification on the vessel floor.

- 40 minutes core plate inspections

- Surveys conducted 29 feet (8.92 meters) above the core plate (prior to core reload)

- Core plate construction surveys – ICI tubes, anti-vibration sleeves, core plate pins

- Limited below core plate inspections from 29 feet (8.92 meters) above core plate

- Entire vessel inspection (when core plate removed) completed in 40 minutes from a height of 37 feet (11.27 meters).

- One Set Up for Multiple Survey Tasks

- Captures entire core/vessel from one location

- No supplemental lighting needed

- Lowers radiation/Reduces dose exposure for personnel

- Accurate underwater measurements do not require tanks and pools to be drained

- LiDAR Enabled Long-Range, Large Area Scans

- 3D Measurable, Millimetric Point Cloud Information

- Accessed anywhere with password protection

- Exports into any standard format in a single file

- Integration of new and historical data

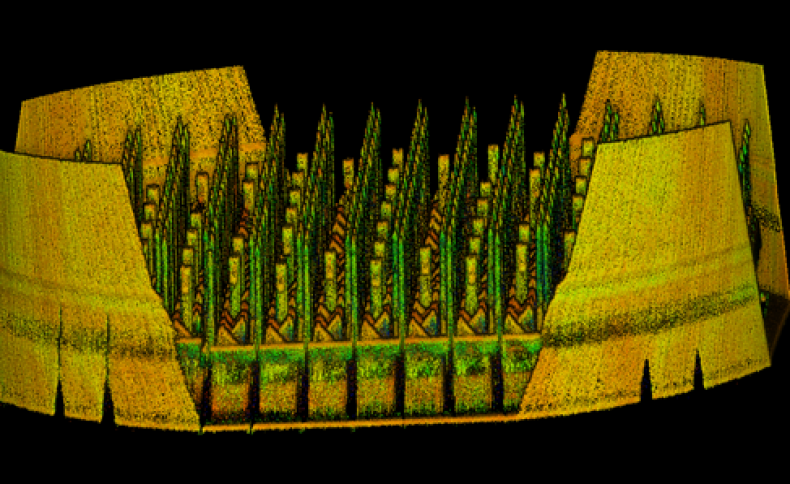

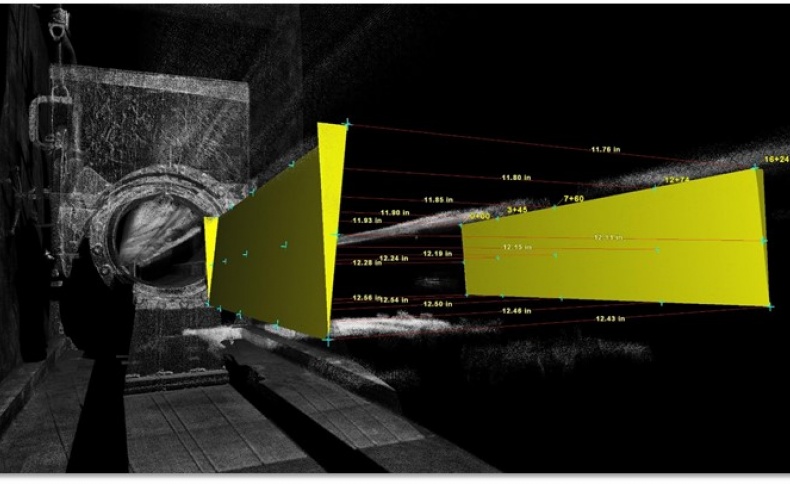

Fuel assembly component placement and fuel assembly positioning can be critical for Pressurized Water Reactors (PWR) and Boiling Water Reactors (BWR). Fuel assemblies and fuel assembly inserts and components are required to be within tight tolerances in height, spacing and distortion (bow/twist). Failure to properly identify these anomalies and errors has led to fuel damage, core redesigns and significant outage delays. Many of these costly overages can be avoided by using SL3n LiDAR laser survey technology. Accurate, repeatable, millimetric 3D LiDAR data sets, which can be exported into any standard format, provide detailed information to prevent, mitigate and enable proactive maintenance and operational actions.

SL3n Value and Benefits

SL3n Value and Benefits

- Mitigates Human Error of Screen Calipers and Guesstimates

- Reduces Survey Completion Times

- Captures Entire Core from a Single Location

- Archival Gap Measurements

- Fuel Gap Analysis

- Fuel Assembly and Distortion (bow/twist) Measurements

- Quick Identification of Core Uniformity

- Control Blade Elevations

- Fuel Assembly Elevations

- Fuel Assembly Insert Placement

- Fuel Assembly Gap Analysis

- Reduces Dose to Personnel

- 3D Measurable, Millimetric Point Cloud Information

- Accessed anywhere with password protection

- Exports into any standard format and a single file

- Integration of new and historical data

Fuel Assembly Gap Measurements

Mitigate Human Error, Evaluate, and Verify

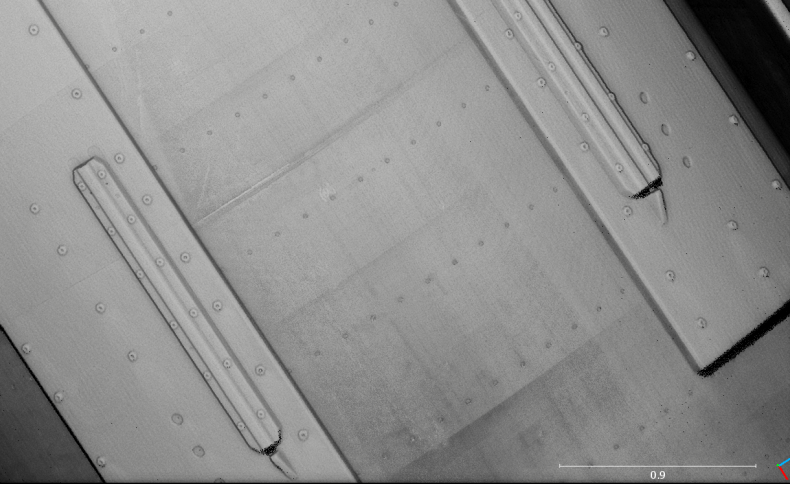

Visual, Underwater, Nondestructive Inspections

Preventative and Proactive Survey Data

SL3n LiDAR laser technology solution enables rapid, visual, measurable, underwater, nondestructive inspections to reduce maintenance and operational shutdowns.

Nondestructive Underwater inspections and examinations (NDIs, NDEs) are a critical part of nuclear power utility maintenance and operational practices. Regular inspections and stringent adherence to guidelines can significantly reduce or even eliminate failures and potential shutdowns. Advanced condition monitoring systems can be used to optimize maintenance decisions and prevent component degradation. The SL3n LiDAR laser provides 3D digital survey information that can mitigate the risk for costly 5,7, and 10 year inspections by providing accurate routine inspections that can provide measurable flaw data (that can be trended, analyzed and evaluated). The SL3n LiDAR laser technology has been used across a wide range of applications to measure, map, locate and analyze components, equipment and systems in hard-to-reach underwater locations. The flexibility of SL3n LiDAR laser provides a nondestructive survey tool that can capture, quantify and identify potential hazards and component deterioration. The SL3n’s measurable, repeatable, millimetric 3D data sets are generated through the patented SL3n laser technology and can be exported into any standard format. Careful analysis of equipment, components, and systems can be imaged, measured, and evaluated in near-real-time.

SL3n Applications for NDI, NDE

SL3n Value and Benefits

Nondestructive Underwater inspections and examinations (NDIs, NDEs) are a critical part of nuclear power utility maintenance and operational practices. Regular inspections and stringent adherence to guidelines can significantly reduce or even eliminate failures and potential shutdowns. Advanced condition monitoring systems can be used to optimize maintenance decisions and prevent component degradation. The SL3n LiDAR laser provides 3D digital survey information that can mitigate the risk for costly 5,7, and 10 year inspections by providing accurate routine inspections that can provide measurable flaw data (that can be trended, analyzed and evaluated). The SL3n LiDAR laser technology has been used across a wide range of applications to measure, map, locate and analyze components, equipment and systems in hard-to-reach underwater locations. The flexibility of SL3n LiDAR laser provides a nondestructive survey tool that can capture, quantify and identify potential hazards and component deterioration. The SL3n’s measurable, repeatable, millimetric 3D data sets are generated through the patented SL3n laser technology and can be exported into any standard format. Careful analysis of equipment, components, and systems can be imaged, measured, and evaluated in near-real-time.

SL3n Applications for NDI, NDE

- Underwater Components

- Upper Internals, Lower Internals, Dryer, Separator, Pumps

- Inservice Internal Tank Inspections

- Baseline Surveys, Archival Data Comparisions, etc.

SL3n Value and Benefits

- Rapid, Underwater, Nondestructive Survey Campaigns

- Large area surveys from one location

- Accurate underwater measurements do not require tanks and pools to be drained

- Not dependent on specific focal length

- Lowers Radiation/Reduces Dose to Personnel

- LiDAR Enabled Long-Range, Large Area Scans

- 3D Measurable, Millimetric Point Cloud Information

- Accessed anywhere with password protection

- Exports into any standard format in a single file

- Integration of new and historical data

Obtaining precise, accurate measurement information can mean the difference between the success and failure of nuclear power generating systems. Large components, miles of piping, and material degradation are the variables for success and failure. The structural integrity of these components and equipment require baseline measurements and monitoring. SL3n LiDAR laser technology enables accurate, high-resolution 3D scans of underwater equipment, systems, and assets. Each scan gathers thousands of measurements that are then converted into data points, which are "stitched" together using a powerful proprietary backend software that easily exports into any format – CAD, CIS, GiS, etc. In addition, the same hardware can acquire vibration information of the equipment from sub-Hertz to > 15kHz. 3D at Depth’s data visualization tools allow engineers and project managers to evaluate, measure, and develop preventive solutions. Every SL3n LiDAR data set can be exported into any standard format to compare, measure, and evaluate with historical information.

SL3n Survey Applications

SL3n Value and Benefits

SL3n Survey Applications

- Metal Fatigue and Material Corrosion Evaluations

- Vibration-Related Piping Surveys – small-bore piping, socket welds, large-bore piping

- Structural Dynamics, Stress Analysis and Vibration surveys.

- Customized Data Acquisition on Vibration

- Leak—Break Evaluations

SL3n Value and Benefits

- Visual, Underwater, Nondestructive Inspections

- Accurate, Millimetric, Measurable 3D Digital Twin Data

- Large Area Data Coverage - due to large stand-off range

Metrologies, Vibration Analysis and Monitoring

Preemptive Data for Operational Efficiencies

Engineering Measurements and Fabrication Support

Accurate, Millimetric 3D Data to Build, Fabricate, and Install

Additive manufacturing technologies are transforming the nuclear industry. The steady demand for replacement components, maintenance overhauls, and compliance requirements, mandate that the design, fabrication, and construction are built around precise, accurate, 3D measurements. Often, plant operators must change out large replacement components that can require custom and bespoke fabrications. In addition, irregularities in component shape for both large and small components add to the complexities in repairs. Successful installations are hinged on taking into account the surrounding environment of the asset placement.

SL3n LiDAR laser surveys provide an exact 3D digital twin to design, build fabricate and install nuclear components and equipment. Each survey generates 3D scans that can provide enhanced information to ensure the success and millimetric accuracy for component and equipment design and fabrication. Surveys campaigns can easily incorporate the surrounding environment or for in-situ placement.

The success of 3D at Depth’s SL3 LiDAR data usages across additive manufacturing projects has been proven across the oil and gas sector. The Company has produced a series of 3D scans for large scale projects including wellhead repair and custom pipeline replacements.

Along with SLn’s value for additive manufacturing and fabrication, 3D at Depth’s engineering capabilities are focused around high-level optical design, embedded processing, high-speed electronics, underwater control equipment, software control, and data processing expertise. The team’s in-house stage-gate development process and proven track record, has successfully brought new technologies to market and provide custom solutions to help clients solve mission critical challenges.

For more information visit our "Design and Engineering Capabilities" page - found here.

SL3n LiDAR laser surveys provide an exact 3D digital twin to design, build fabricate and install nuclear components and equipment. Each survey generates 3D scans that can provide enhanced information to ensure the success and millimetric accuracy for component and equipment design and fabrication. Surveys campaigns can easily incorporate the surrounding environment or for in-situ placement.

The success of 3D at Depth’s SL3 LiDAR data usages across additive manufacturing projects has been proven across the oil and gas sector. The Company has produced a series of 3D scans for large scale projects including wellhead repair and custom pipeline replacements.

Along with SLn’s value for additive manufacturing and fabrication, 3D at Depth’s engineering capabilities are focused around high-level optical design, embedded processing, high-speed electronics, underwater control equipment, software control, and data processing expertise. The team’s in-house stage-gate development process and proven track record, has successfully brought new technologies to market and provide custom solutions to help clients solve mission critical challenges.

For more information visit our "Design and Engineering Capabilities" page - found here.

The SL3n LiDAR laser technology provides enhanced 3D data to help facilitate the license renewal process for the United States operated and maintained nuclear plant facilities. The aging degradation of PWR reactor pressure vessel internals, and BWR reactors crack initiation and growth, have become a high priority as nuclear facilities approach and enter license renewal periods. Renewal applications must consider the effects of aging in order to meet conditions defined in the Nuclear Regulatory Commission's (RNC) Generic Aging Lessons Learned Report. In response, the Materials Reliability Program’s (MRP's) Reactor Internals Focus Group (RI-FG) has prepared inspection and evaluation guidelines for managing the effects of aging degradation in PWR internals. The guidelines, issued under the NEI 03-08 Materials Initiative, include developing an Aging Management Program (AMP) and inspection plan for PWR/BWR internals. As an additional "tool" in the toolkit, SL3n can be used across license renewal survey data requirements to help in-house and external consultants with their MRP 227-A evaluation and analysis.

SL3n LiDAR technology provides millimetric, repeatable, 3D point cloud survey data acquisition campaigns to support license renewal application requirements. Our 3D LiDAR data support technicians can work across survey campaign to help integrate 3D LiDAR data with historical data information to expedite the application process.

SL3n Value and Benefits

SL3n LiDAR technology provides millimetric, repeatable, 3D point cloud survey data acquisition campaigns to support license renewal application requirements. Our 3D LiDAR data support technicians can work across survey campaign to help integrate 3D LiDAR data with historical data information to expedite the application process.

SL3n Value and Benefits

- Reduce Outage and Maintenance Time for Inspections

- Low-Cost Routine Monitoring

- Trend Data and Reviews

- Analysis Capabilities - current, historical, and future modeling

- Avoid Costly Large Scale Inspections

- LiDAR Enabled Large Area Scanning from One Location

- Baseline Data for Routine Trending

- Structural Integrity and Degradation Surveys

- Generic Aging Management Surveys for BWR Reactor Coolant Systems

- Time Limited Aging Analysis

- ASME XI Inservice Inspections

Support for License Renewal/Subsequent License Renewal Inspections

Document, Validate, and Expedite

Balance of Plant Water System Survey Inspections and Measurements

Inspect, Evaluate, and Diagnose

Nuclear reactors generating electricity in the United States fall into two main categories: Boiling Water Reactors (BWRs) and Pressurized Water Reactors (PWRs). Both systems boil water to make steam (BWRs within the reactor and PWRs outside the reactor); in both cases, this steam must be cooled after it runs through a turbine to produce electricity. In order to get comprehensive survey data, underwater structures must be drained or human divers must be contracted to perform inspections and measurements. Both of these options are labor intensive, costly, include human risk, not to mention reactor downtime. SL3n enables remote visual inspections with comprehensive 3D data collection that can accurately diagnose a wide range of operational risks:

Along with internal plant water cooling system issues, external water intake systems can also pose a problem. Intake sources can become clogged with debris, biofouled, or damaged due to external climate conditions. Those areas include:

SL3n Value and Benefits

- Pipe discontinuities, such as cracks, breaks,

- Debris that may cause failure to your system

- Cracks in the structure

- Components and equipment movement due to pump action

Along with internal plant water cooling system issues, external water intake systems can also pose a problem. Intake sources can become clogged with debris, biofouled, or damaged due to external climate conditions. Those areas include:

- Water Intake, Discharge, and Circulatory Water Systems and Pumps

- External Environmental Hydrographic Surveys

- Pipe inspection

SL3n Value and Benefits

- Eliminate Draining System

- Trend, Integrate, Analyze and Evaluate - current, historical, and future modeling

- Structural Integrity and degradation surveys

- Flexible, Standard Views that Export – AutoCAD, ASC etc.

3D at Depth SL3n solution and proprietary Augmented Reality/Virtual Reality technology delivers an interactive training tool to help increase the competencies of nuclear plant employees and partners. Employees can maintain and improve high standards of safety, reliability, and availability on the plant premises - saving travel costs, reducing risk, and satisfying credential requirements. Access to high-risk environments is minimized through robust 3D data models that can be imported and manipulated for real-world modulations and simulation exercises.

Challenging problems occur regularly at any nuclear facility. With the right expertise, you can solve those challenges faster, before small issues become significant threats.

3D at Depth Training Solution

Challenging problems occur regularly at any nuclear facility. With the right expertise, you can solve those challenges faster, before small issues become significant threats.

3D at Depth Training Solution

- Interactive Training with Practical Applications

- Real-World Model to Build Knowledge

- Reduce Risk

- Cost-Benefit

Training and Simulations Models - AR/VR and 3D Data Analysis

Reduce Risk and Empower Decisions