Advanced Product Design

Overview

Our professional design team provides technical expertise and best practices for the development, design and build of custom products for subsea and marine customers worldwide. With backgrounds that span aerospace, telecommunications, consumer electronics and the offshore oil and gas industry, the team has an interdisciplinary approach to drive innovation, launch new products, and bring new ideas to commercialization.

3D at Depth focuses around our high-level optical design, software control, and data processing expertise. With our in-house developed stage-gate process and proven track record, the team has successfully brought new technologies to market.

3D at Depth focuses around our high-level optical design, software control, and data processing expertise. With our in-house developed stage-gate process and proven track record, the team has successfully brought new technologies to market.

Data processing

- Data Analytics

- Simulation

- Data workflows

- Change detection and analytics

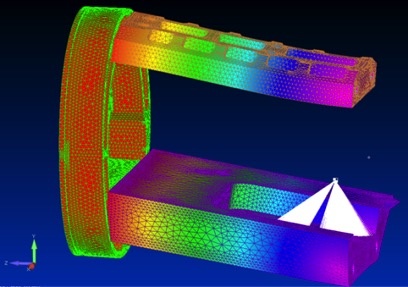

System Design

- System Architecture for subsea components, especially optically based

- System level sensor performance modeling, eye safety certifications

- Project management – initial concept to production

Manufacturing

- Incoming Inspection System

- Inventory Systems (MRP)

- Material Control Process

- Document Control System

- Manufacturing Test Systems

- Software Revision Control System • Internal/In Process Audits

Test

- Reliability – temperature cycling (air and water), vibration, shock, drop

- Component and system level tests (air and water)

Remote Sensing

In order to support the decision-making process across production and exploration, the technology development required design considerations from pre-project planning to data processing and control. An additional feature provides flexibility for those vessels with low bandwidth communications to shore. 3D at Depth’s Compressed Remote Command and Control solution enables full control with bandwidths of just 4kb/second, allowing data to be collected offshore and stored on the sensor or a topside computer. The near real-time data quality control is achieved using an improved and trusted enhancement of the RIAAT format and newly named, Compressed Range Intensity Angle Angle Time (cRIAAT). This improved feature enables moving a scan location with bandwidths of 200kb/second less than the collection time. This flexibility allows an onshore operator to receive data and start processing with little or no delays to the offshore operation. This approach can be utilized on many offshore applications including leak detection, static field scans, and metrologies.

The flexibility of third-party system incorporation, such as offshore connectivity allows for varying vessel specifications of ship-to-shore communications capabilities. The short base system is capable of running over a normal 4G network without delays. This allows a 3D at Depth Subsea LiDAR Specialist to collect from a customer's worksite/location or one of 3D at Depth's global office locations. This is especially important during extreme weather events onshore or with complex secure locations where external or outside companies have restrictions on connecting to the client network.

A key added value of 3D at Depth's remote sensing and remote data control solution is the ability to collect offshore, then process and release onshore. The fast turnaround and shore-based Quality Control leverage the company’s resources and expertise across global time zones. From Houston, Texas, to Perth, Australia with our centrally located United Kingdom office, 3D at Depth delivers true global remoted collection 24/7 without the extended working hours in any one office location.

The flexibility of third-party system incorporation, such as offshore connectivity allows for varying vessel specifications of ship-to-shore communications capabilities. The short base system is capable of running over a normal 4G network without delays. This allows a 3D at Depth Subsea LiDAR Specialist to collect from a customer's worksite/location or one of 3D at Depth's global office locations. This is especially important during extreme weather events onshore or with complex secure locations where external or outside companies have restrictions on connecting to the client network.

A key added value of 3D at Depth's remote sensing and remote data control solution is the ability to collect offshore, then process and release onshore. The fast turnaround and shore-based Quality Control leverage the company’s resources and expertise across global time zones. From Houston, Texas, to Perth, Australia with our centrally located United Kingdom office, 3D at Depth delivers true global remoted collection 24/7 without the extended working hours in any one office location.

Subsea Integration Services

The harsh subsea environment of offshore and marine operations requires a unique knowledge base to enable integrated solutions for cost-effective project completion. 3D at Depth’s global team of professionals have extensive industry experience and know how for air-to-water interfacing of sensors for a wide variety of offshore applications. Our proven capabilities support turnkey solutions for diver systems, ROVs, AUVs and surface vessel integration, along with remote sensing and statically deployed packages. Each project engagement provides full-cycle development from conceptual design, delivery and production of operational devices.